Chiller Introduction:

Chiller is a water cooling equipment, chiller is a can provide constant temperature, constant current, constant pressure cooling water equipment. Chiller according to the form of refrigeration can be generally divided into water-cooled and air-cooled, technically, water-cooled air-cooled energy efficiency ratio is higher than 300 to 500 kcal / h; in price, water-cooled than air-cooled Much lower; in the installation, water-cooled to be included in the cooling tower before use, air-cooled is removable, no other auxiliary, but the air-cooled chiller fan cooling, environmental requirements

Water cooling type:

Chiller use:

Chiller used in plastic processing machinery mold cooling can greatly enhance the surface finish of plastic products, to reduce internal stress marks and surface texture of plastic products, so that product does not shrink, without distortion, to facilitate stripping of plastic products, accelerate product shape, so that a very large increase production efficiency of plastic molding machines.

Water-cooled chiller features:

1.stable performance: the use of multiple compressors in parallel, each compressor comes with a separate refrigeration circuit, that is, evaporator, condenser is completely independent; all compressors by a unified micro-computer control system, one by one on and off , Each other will not interfere with each other, with all the original brand of genuine machine production, single failure rate is very low, the above reasons, you can ensure that the series has a highly stable performance, continuous operation for many years Preferred, without having to buy another spare machine;

2.energy saving: the use of a number of small and medium power compressors in parallel, open, shut down when the interference on the grid is minimal, with the load changes, the unit will automatically determine the number of boot, to ensure that the compressor is turned on the best work State, thus effectively saving electricity;

3.long service life: evaporator, condenser design is very reasonable, and placed in the compressor above, throughout the operation, most of the lubricating oil remain in the compressor, to ensure good lubrication of the compressor.

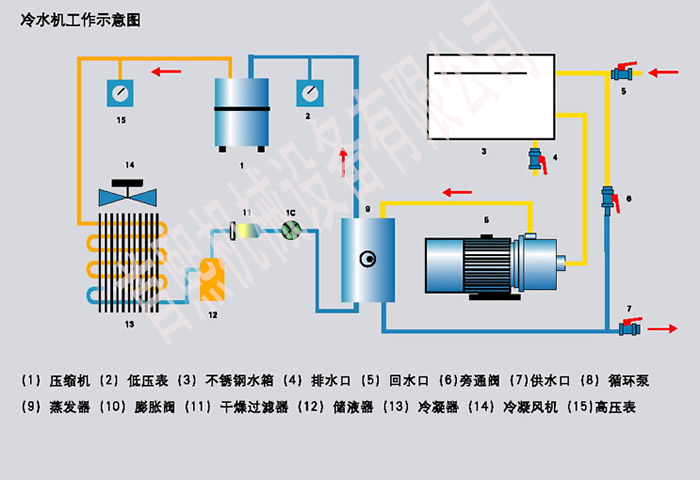

Water-cooled chiller works:

A certain amount of water is injected into the water tank of the engine, the water is cooled by a chiller refrigeration system, and then the water pump delivers the low-temperature cooling water to the equipment to be cooled, the chilled water of the chiller will take the heat away and then return to the water tank, Achieve cooling effect. Cooling water temperature can be automatically adjusted according to requirements, long-term use can save water. Therefore, chiller is a standard energy-saving equipment.

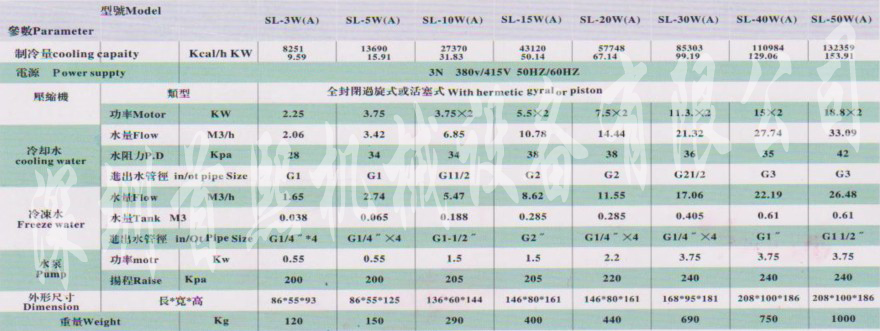

Water-cooled chiller technical parameters: